Rotor Impeller Repair: A Case Study

Discover More

14th January 2026

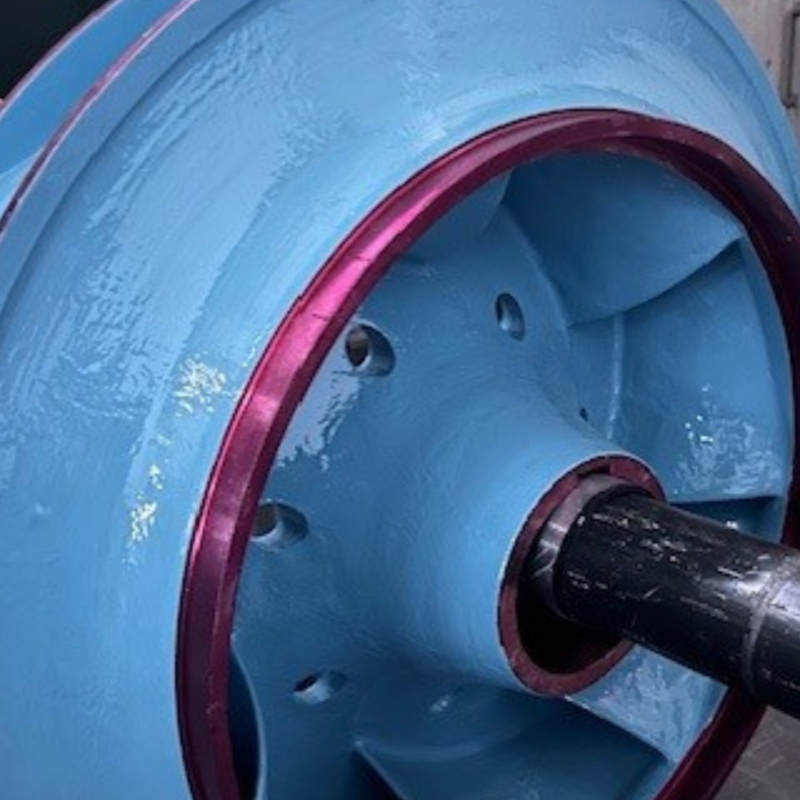

Resimac’s Rotor Impeller Repair Solution

- Rebuilt damaged areas with 101 Metal Repair Paste.

- Applied Resimac 203 Super Flow in a single coat for comprehensive protection.

- Stationary parts coated with Resimac 501 ARXL for abrasion resistance.

Application Details

The most severe cavitation damage was addressed through welding to restore the structural integrity of the impellers. Resimac’s 101 Metal Repair Paste was then applied to remaining surface imperfections, ensuring a smooth and uniform profile suitable for subsequent coatings. This step was critical to achieving a durable, high-performance finish.

To accommodate the cold winter conditions, 203 Super Flow was applied in a single, high build coat. Skilled applicators carefully controlled the thickness to ensure uniform coverage and consistent protection, even with the increased viscosity caused by low substrate temperatures. On stationary components with milder wear and abrasion, 501 ARXL was applied as a single coat, delivering effective resistance to wear while maintaining application efficiency.

Products Used

Results and Benefits

The repair delivered significant benefits beyond restoring the impellers. It provided a durable solution that aligned with the plant’s long term operational goals, ensuring consistent performance under demanding conditions. The tailored approach minimised disruption, allowing the refurbishment to be completed efficiently despite winter challenges.

This project also demonstrated the versatility of Resimac products, showcasing their capability to meet specific requirements while maintaining high performance. By extending the lifespan of the pump, the repair contributed to sustainable practices, reducing material waste and the environmental footprint associated with frequent replacements.

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.