Anti-Slip Floor Coating: Ferry Deck, UK

Discover More

19th November 2024

Industry: Marine

Location: UK

Application: Anti Slip Floor Coating

Products: 507 DWPU

The Challenge

A ferry operator in the UK experienced recurring vehicle slippage on loading ramps and decks, particularly during wet weather. These hazardous conditions compromised operational safety and increased the risk of transit related accidents. To mitigate these risks, the operator required a high durability anti slip floor coating system capable of providing reliable traction and long term surface protection under heavy, daily maritime use.

The Solution

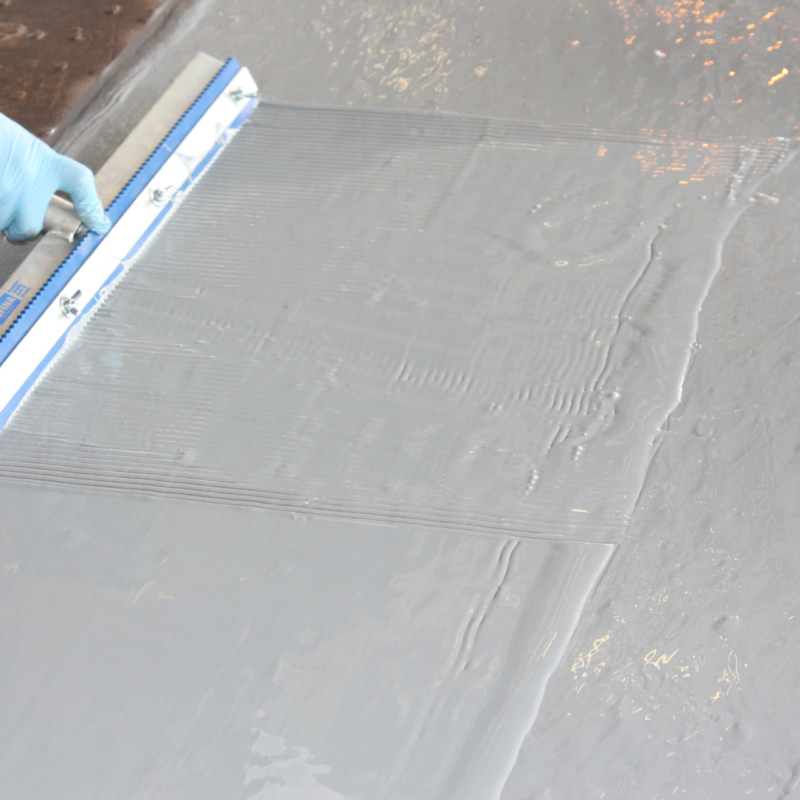

The first step in the process was marking the areas of the deck to be coated. The steel substrate was then thoroughly prepared by abrasive grit blasting to achieve a SA2.5 standard and a 75-micron profile. This step was essential to ensure optimal adhesion for the coating. After preparation, 507 DWPU was applied by both brush and roller to a 1mm thickness while still wet. The aluminium oxide aggregate, chosen for its durability and size (2mm particles), was broadcast over the wet surface. Once the coating cured, excess aggregate was swept and vacuumed away, leaving behind a textured, non-slip surface designed to withstand wear and tear from frequent vehicle traffic.

Results & Benefits

- Resimac 507 DWPU with aluminium oxide aggregate created a durable, anti-slip surface to significantly improve vehicle traction

- The textured, high wear finish reduced accident risks and enhanced safety across all ferry loading areas

- The marine grade coating ensured long term durability, extending the lifespan of both the deck and ramp

- This cost effective solution minimised the need for frequent repairs in high traffic zones

- The two coat system allows for easy visual inspection to identify and manage wear over time

- Maintains its structural integrity and colour stability against harsh UV radiation and extreme weather conditions

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.