Ceramic Epoxy: Asset Protection & Repair

Discover More

12th January 2026

What is Ceramic Epoxy?

A ceramic epoxy is a high performance polymer composite reinforced with hardened ceramic aggregates, typically silicon carbide or aluminium oxide. Unlike standard protective paints, this material is designed as a load bearing barrier.

By embedding industrial grade ceramics into our epoxy materials, the industrial ceramic coating functions as a superior wear resistant barrier. It is specifically designed to absorb heavy mechanical impacts and resist the aggressive sliding abrasion caused by aggressive slurries and abrasive particulates.

A high quality wear coating used for extending the lifespan of assets in environments where traditional coatings would fail!

Solving Erosion & Corrosion with Ceramic Epoxy Systems

In the industrial environment, the true cost of an asset isn’t its purchase price, it’s the cost of downtime. When engineers & asset mangers choose a Resimac industrial ceramic epoxy, they are they are implementing a performance upgrade that addresses three critical operational needs.

- Eliminating Wear & Tear: Ceramic epoxy systems create an ultra hard barrier designed to withstand aggressive environments. This shields components such as pumps, impellers, and pipe elbows from abrasive grit and slurries, ensuring assets remain operational.

- Reduced Costs: These coatings do more than just protect, they optimise. By creating a smooth, low friction surface, ceramic epoxy’s allow fluids to move more freely. This reduces the workload on motors, lowering energy costs and helping your facility meet 2026 carbon reduction targets.

- Avoid Expensive Replacements: Our coatings function as a durable barrier, by absorbing mechanical impact and wear, they protect the base metal, reducing the need for costly replacement parts and lengthy downtime.

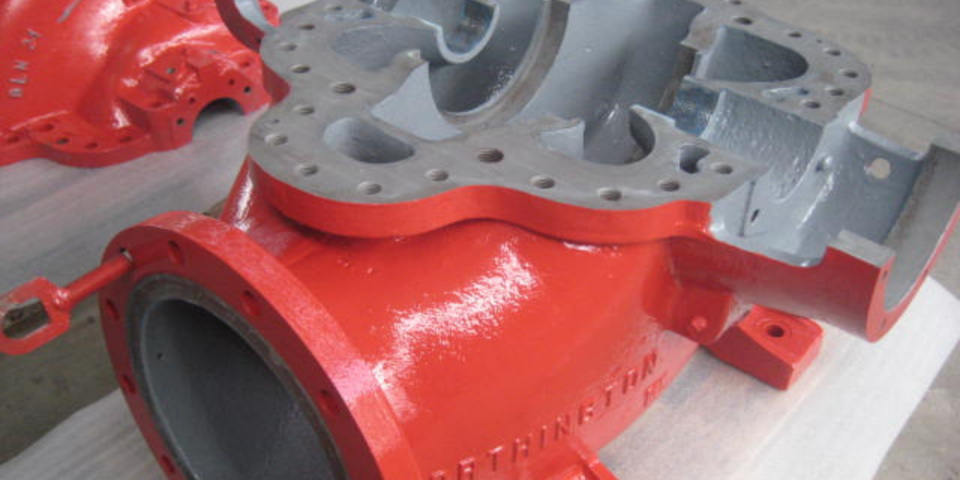

Resimac Real Word Case Study

Industry: Power Generation Location: Italy Application: Industrial Seawater Pump

Repair Products: 201 Ceramic Repair Paste & 202 Ceramic Repair Fluid

View more metal repair and protection case studies

Identifying the Right Ceramic Solution for Your Application

Whether you are dealing with a wastewater silo, a chemical pump, or a high traffic loading ramp, choosing the right wear coating is essential. Resimac’s industrial ceramic coating technology is designed for rapid application and long term durability, providing a specialised wear coating for every industrial challenge.

Resimac Rebuilding & Repair Pastes

- 201 Ceramic Repair Paste: Solvent free epoxy paste used to fill surface erosion and pitting on metallic surfaces

- 204 Heavy Duty Ceramic Repair Paste: Contains 0.2mm–1.2mm ceramic beads for extreme resistance to sliding abrasion in heavy processing environments

-

204 HD Paste: Contains 1mm–1.5mm ceramic beads. It is specifically designed for extreme sliding wear and erosion caused by wet slurries and larger aggregate flow

- 204 UHD Paste: An ultra high density version of the 204 HD system. It combines ceramic beads with a specialized energy-absorbing resin to withstand the most severe environments involving both extreme sliding abrasion and heavy mechanical impact.

- 204 XHT Paste: A ceramic reinforced paste designed specifically for extreme high temperature environments

Resimac Protective Coatings & Fluids

- 202 Ceramic Repair Fluid: A brushable reinforced epoxy fluid, ideal for resurfacing metallic components exposed to aggressive fluid flow

- 203 Super Flow: A specialised ceramic coating used to improve fluid flow efficiency while protecting against erosion corrosion

- 208 Ceramic UW: Specifically formulated for application to wet or underwater surfaces, such as splash zones and subsea structures

Resimac High Temperature Systems

- 205 Ceramic HT Fluid: A solvent free epoxy novolac coating for high temperature immersion, up to 130°C (265°F) in hydrocarbon or aqueous applications

- 206 Ceramic HTA Fluid: A durable reinforced novolac coating for high temperature immersion in acidic environments

- 207 Ceramic XHT Fluid: Designed for extreme temperature immersion, resisting fluid flow up to 180°C (356°F)

Why Choose Resimac Ceramic Epoxies?

Ceramic enhanced epoxies are engineered for environments where standard coatings fail due to extreme wear, fluid flow, or impact.

- Extreme abrasion resistance

- Enhanced cavitation protection

- Superior erosion resistance

- Optimised fluid flow efficiency

- Reduced sacrificial metal loss

- Lowered energy consumption

- Minimised downtime for relining

Categorised in: News

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.