Corroded Pipe Repair: Seawater Pipelines, Korea

Discover More

5th December 2024

Industry: Marine

Location: Korea

Application: Corroded Pipe Repair

Products: 501 ARXL

The Challenge

During a routine inspection of a container transporter vessel, engineers discovered extensive erosion and metal loss within the critical seawater transportation pipes, particularly at vulnerable bends and junction pieces where fluid dynamics are most aggressive. The severity of the damage compromised the vessel’s operational safety and required an immediate, comprehensive corroded pipe repair and replacement strategy, with the core challenge being the implementation of a durable barrier capable of resisting relentless seawater corrosion and intense internal fluid dynamics over many years of service.

The Solution

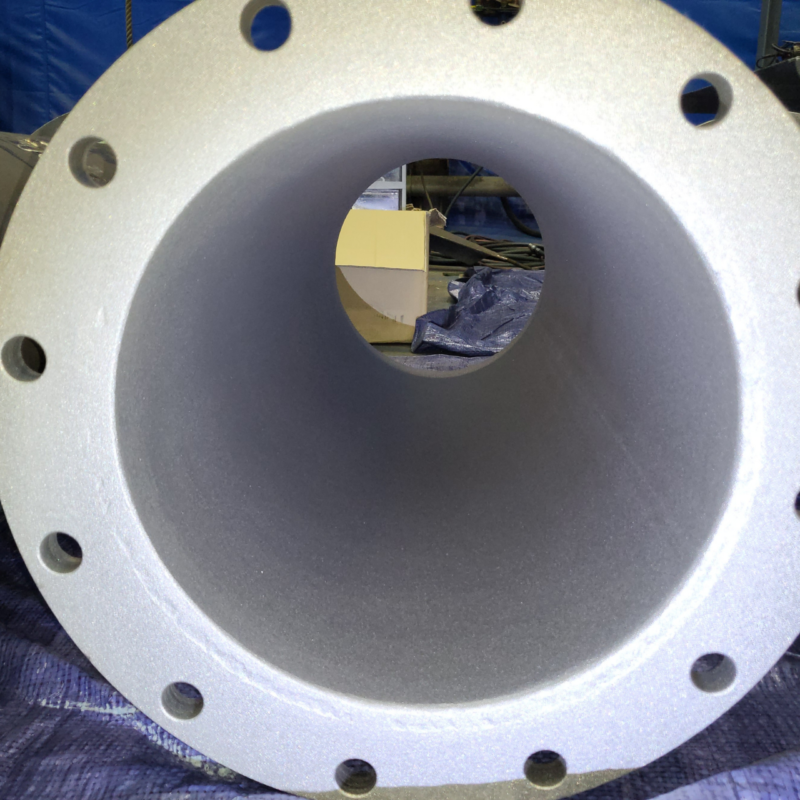

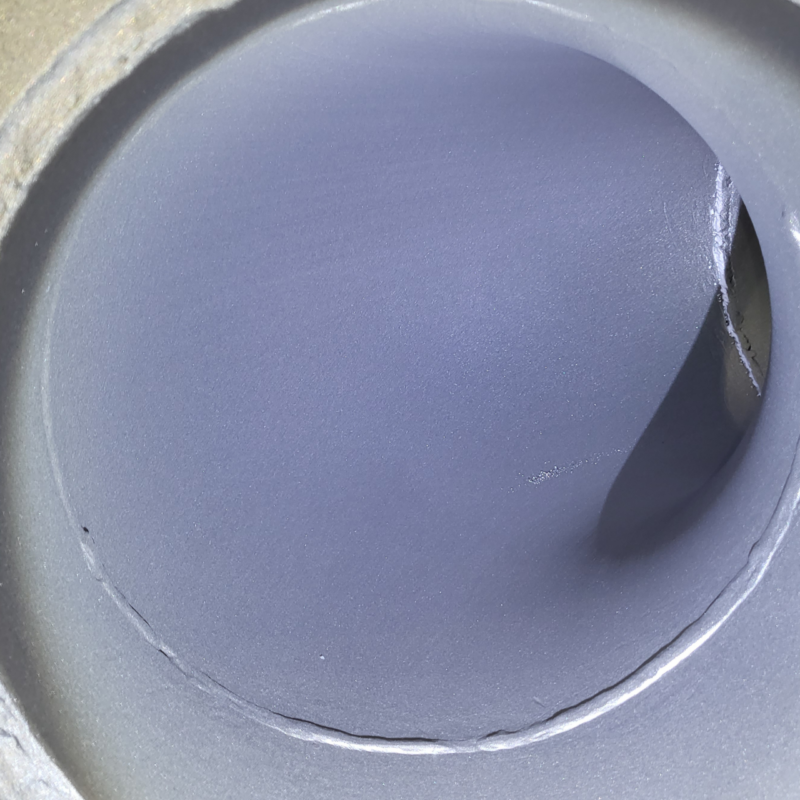

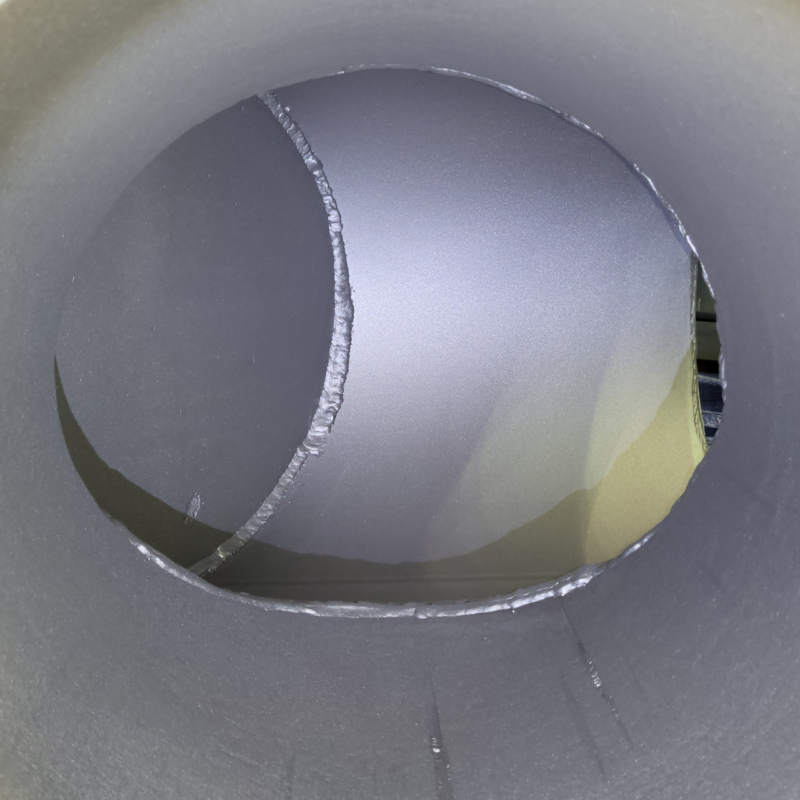

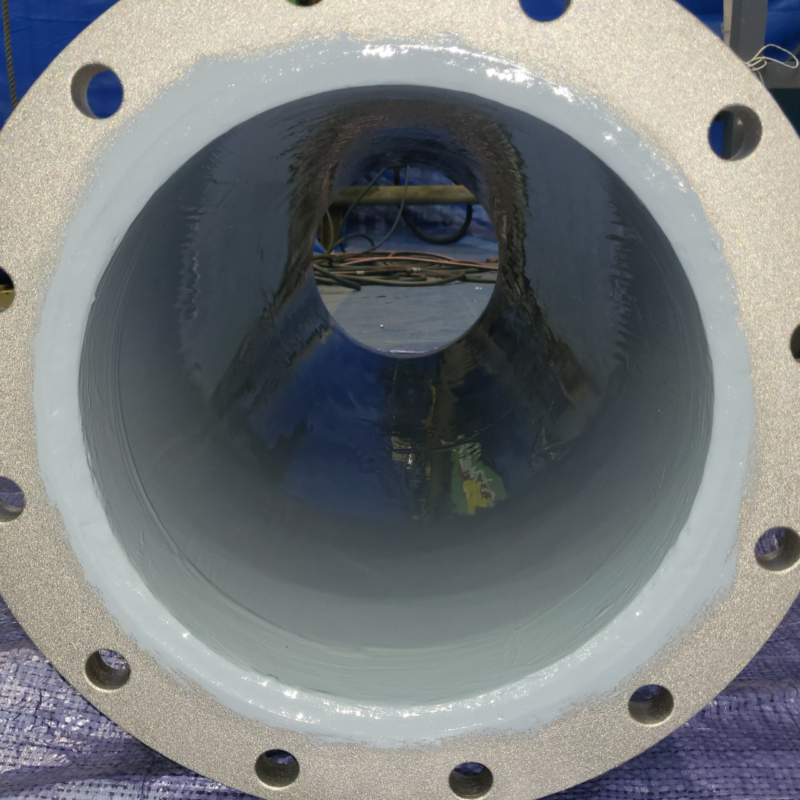

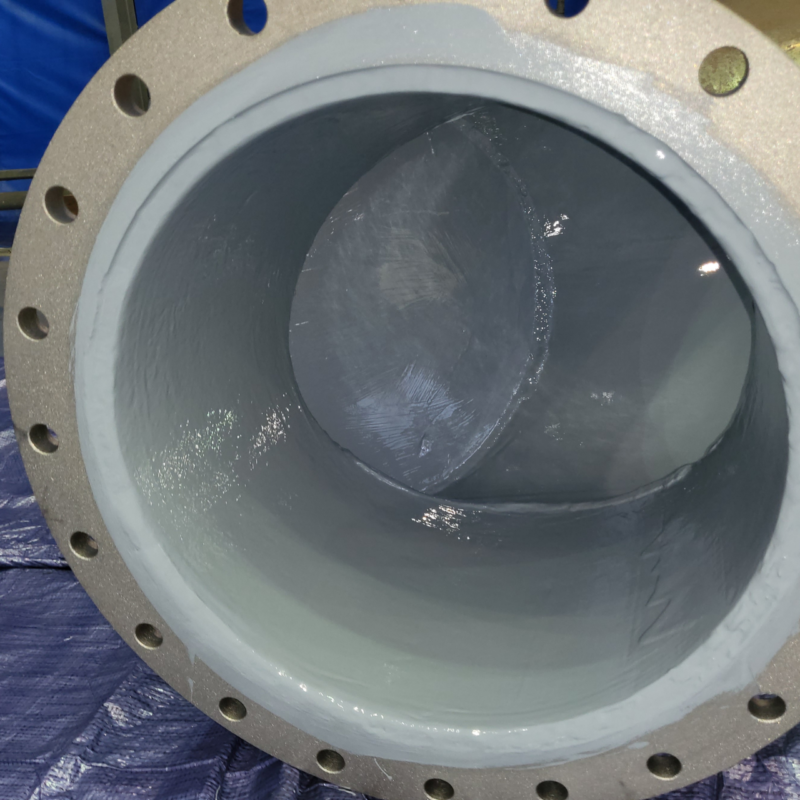

The corroded pipe repair strategy focused on pre-treating and coating new mild steel sections before installation to ensure maximum longevity. To facilitate superior mechanical adhesion, the new steel was abrasive grit blasted to an SA2.5 (ISO 8501) standard with a 75-micron angular profile. Technicians then manually applied of two layers of 501 ARXL using brushes and rollers. This hand application method ensured that the complex geometry of the new pipe bends and junctions received complete coverage.

Each coat was applied to a nominal thickness of 450 microns, resulting in a high build, 900-micron total barrier. This specific 501 ARXL system was chosen to shield the new steel substrate from the abrasive and electrochemical demands of the marine environment, effectively isolating the metal from the corrosive electrolyte. By coating the new pipes before they entered service, the project provided a permanent fix to the vessel’s ongoing corrosion issues.

Results & Benefits

- Replacing damaged sections with pre-coated pipes significantly extends the operational lifespan of the vessel’s cooling system

- The 501 ARXL barrier prevents metal loss in vulnerable bends and junctions where seawater turbulence is highest

- This proactive corroded pipe repair method eliminates the need for frequent inspections and emergency patches

- By installing protected replacements, the solution avoids the high costs associated with repeated parts replacement and unplanned dry-docking

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.