Corrosion Treatment for Steel Bridge: A Case Study

Discover More

14th January 2026

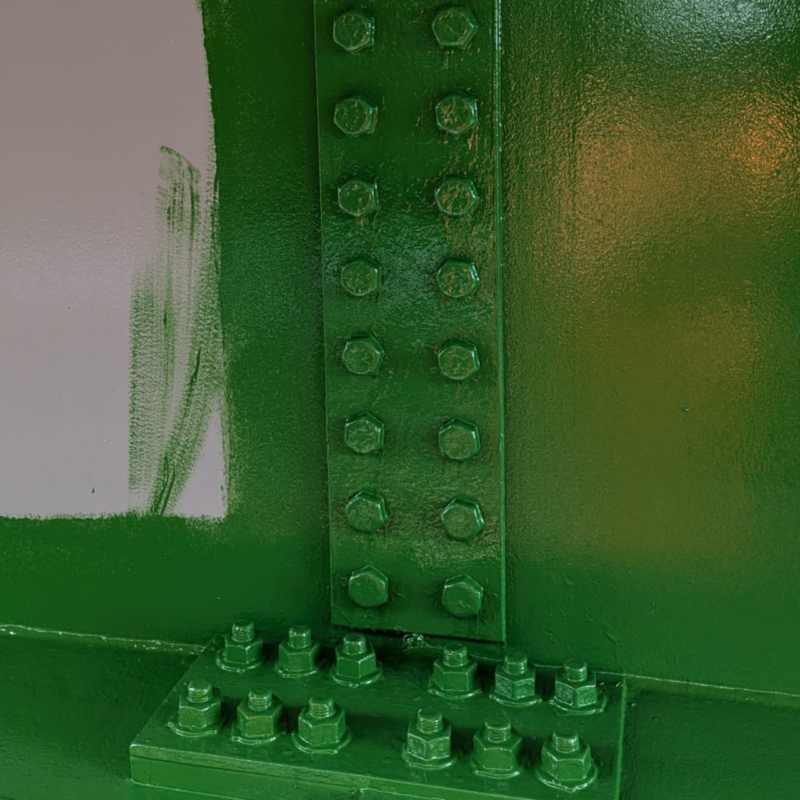

A steel bridge structure in the UK had experienced significant weathering over time, leading to the breakdown of its protective coating system. This deterioration exposed vulnerable areas to environmental damage, increasing the risk of corrosion and structural degradation. A comprehensive corrosion treatment for steel was essential to restore the bridge’s structural integrity. The solution also required the application of a UV stable finish, ensuring that the bridge’s appearance and protective properties would remain intact throughout its lifespan, even under prolonged exposure to harsh weather and sunlight.

Resimac’s Corrosion Treatment for Steel Bridge Solution

- Cleaned and abraded all surfaces, removing loose coatings.

- Applied a primer coat of 506 Aluprime to vulnerable areas.

- Applied a full protective system of two coats of 506 Aluprime and two coats of 508 UVPU to all surfaces.

Application Details

The project was carried out by a Resimac Approved UK Contractor, ensuring expert application of the coating system. The refurbishment process began with thorough cleaning and abrading of the bridge’s steel infrastructure to remove all loose and friable coatings and expose a sound edge. This step ensured a solid foundation for the new protective system.

A primer coat of 506 Aluprime was applied to vulnerable areas, offering additional protection in regions prone to accelerated wear. The full protective coating system followed, consisting of two coats of 506 Aluprime and two coats of 508 UVPU. This system was designed to provide durable resistance against environmental exposure while ensuring a smooth and aesthetically pleasing finish.

All application work was monitored and inspected by a qualified NACE III coatings inspector to ensure adherence to the highest industry standards.

Products Used

Results and Benefits

The refurbishment restored the bridge’s steel structure, providing long lasting resistance to corrosion and environmental wear. The UV stable coating system ensured the bridge maintained its specified colour and protection throughout its lifespan, even in harsh outdoor conditions. This durable finish reduced the need for frequent maintenance, offering both cost savings and minimal disruption.

By extending the bridge’s lifespan, the refurbishment avoided costly structural repairs and downtime, while maintaining its aesthetic integrity. The high performance coating system not only protected the steel but also ensured the bridge remained visually appealing over time, meeting both technical and aesthetic requirements for infrastructure projects.

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.