Industrial Water Filtration Repair: Salt Water, China

Discover More

11th October 2024

Industry: Marine

Location: China

Application: Industrial Water Filtration system

Products: 202 Ceramic Repair Fluid

The Challenge

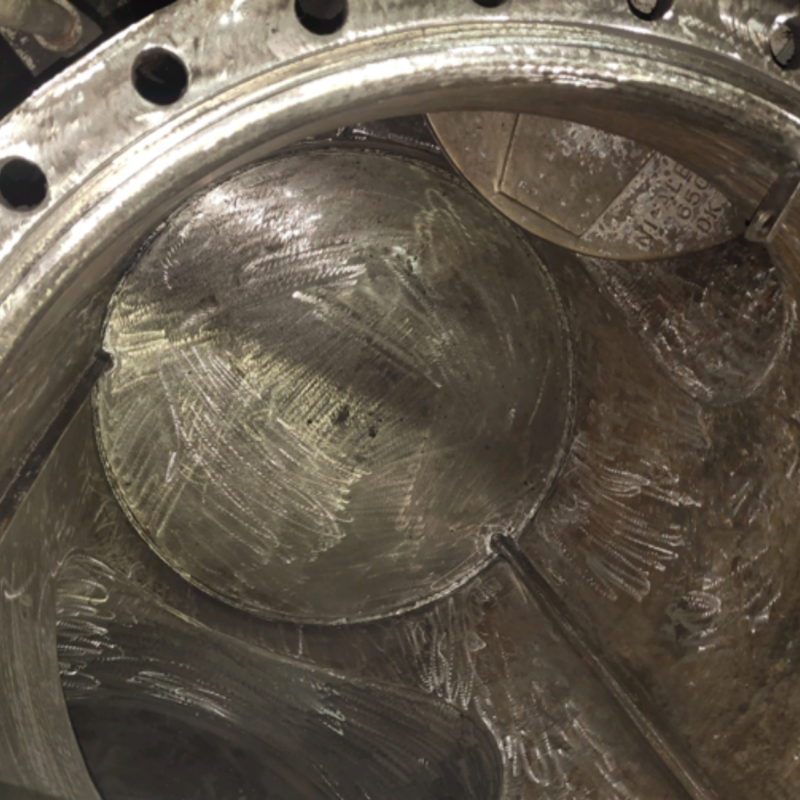

A container ship’s industrial water filtration system suffered from extensive internal corrosion, threatening the efficiency of its seawater intake. The filters required thorough restoration to eliminate corrosion and ensure long term protection. The customer sought a robust solution to protect the salt water filtration systems and minimise future maintenance.

The Application

The internal surfaces were thoroughly cleaned using high pressure fresh water, effectively removing salt contamination and providing a clean base for further treatment. The filter surfaces were then abraded to SSPC SP3 (ISO 8504-1 ST3) standards to prepare for coating.

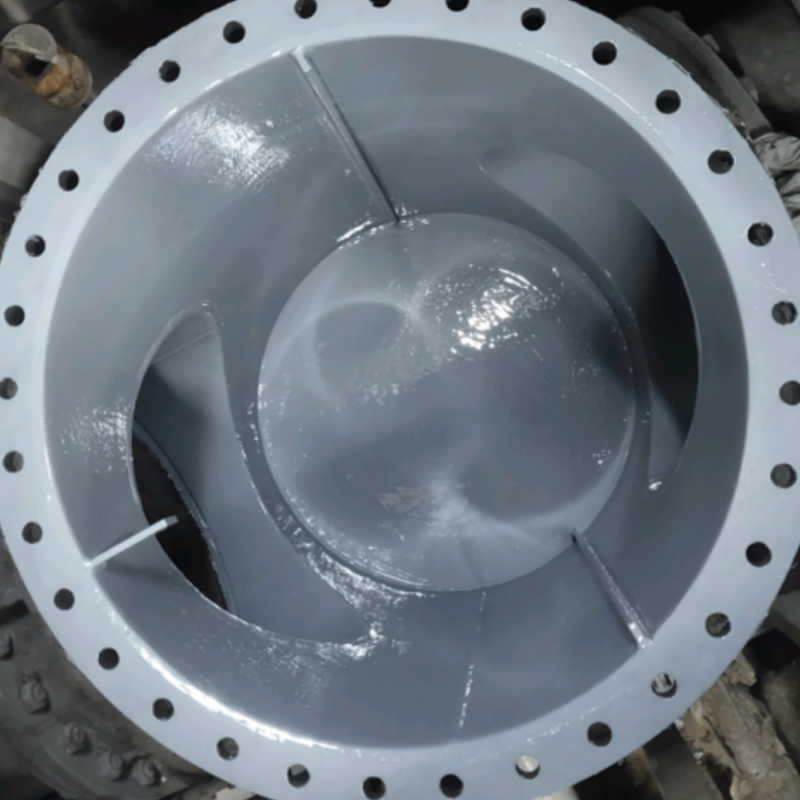

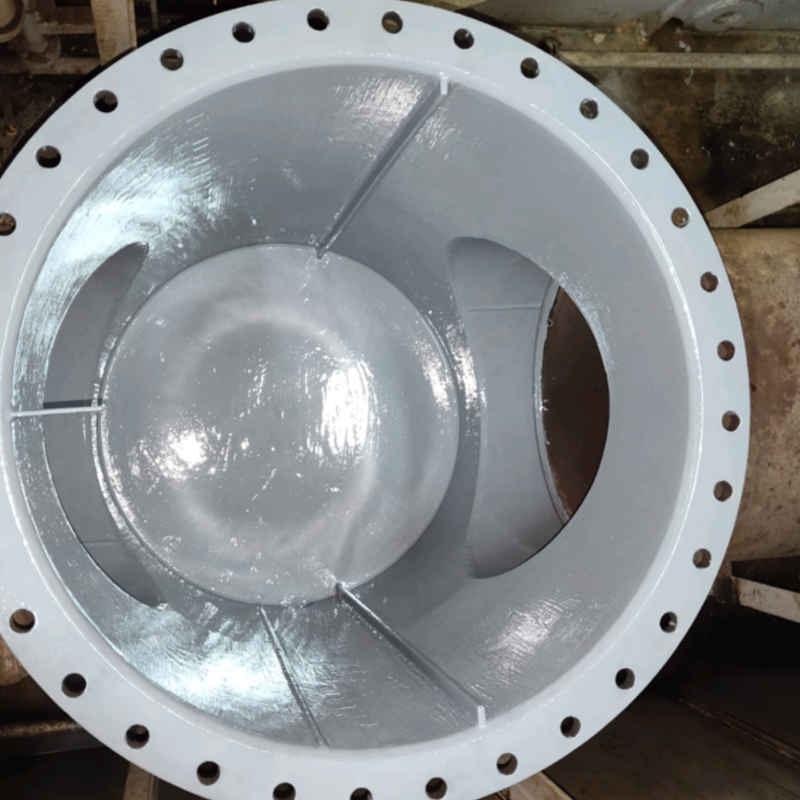

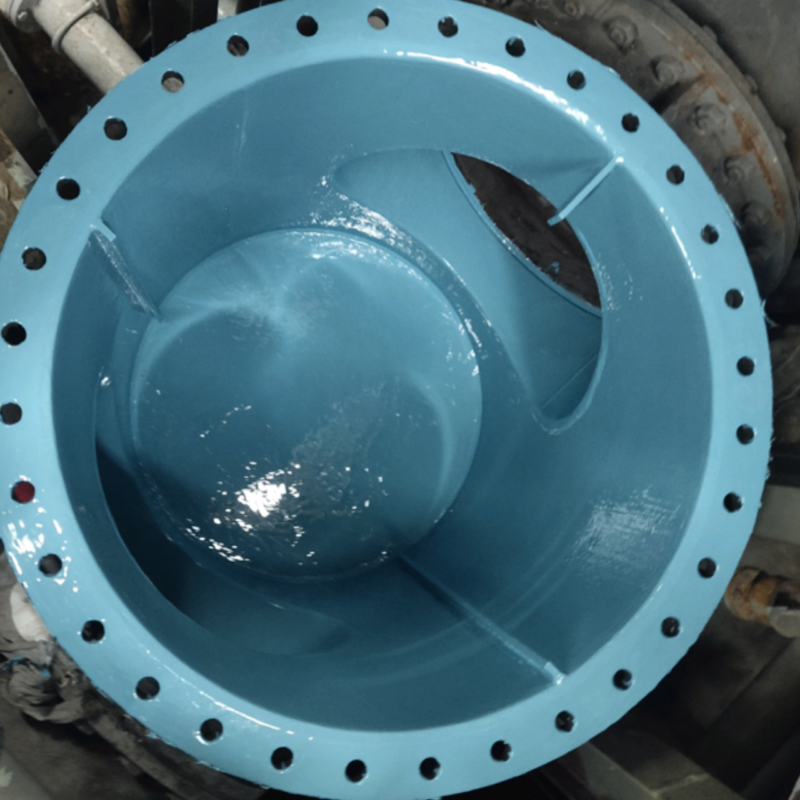

Two coats of 202 Ceramic Repair Fluid were applied to protect the filters and provide long term resistance against abrasion, corrosion, and operational wear.

The Solution

The internal surfaces of the filters were abraded using handheld mechanical grinding tools to achieve the necessary surface profile. Afterward, the surfaces were cleaned with solvent to remove any remaining debris. Resimac’s 202 Ceramic Repair Fluid was applied in two coats using a brush, with each coat providing a nominal dry film thickness of 600 microns.

This robust coating ensured the seawater filters would withstand the harsh marine environment and prolonged exposure to seawater.

Results and Benefits

- The restoration provided long term protection of the ship’s industrial water filtration system

- Protective barrier against corrosion & abrasion

- Improved integrity and performance of the vessel

- Reduced maintenance requirements

- Extended the lifespan of the salt water filtration systems

- Cost effective alternative to a full replacement

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.