Propeller Cone Repair: Marine Ship, Italy

Discover More

3rd December 2024

Industry: Marine

Location: Italy

Application: Propeller Cone Repair

Products: 507 DWPU

The Challenge

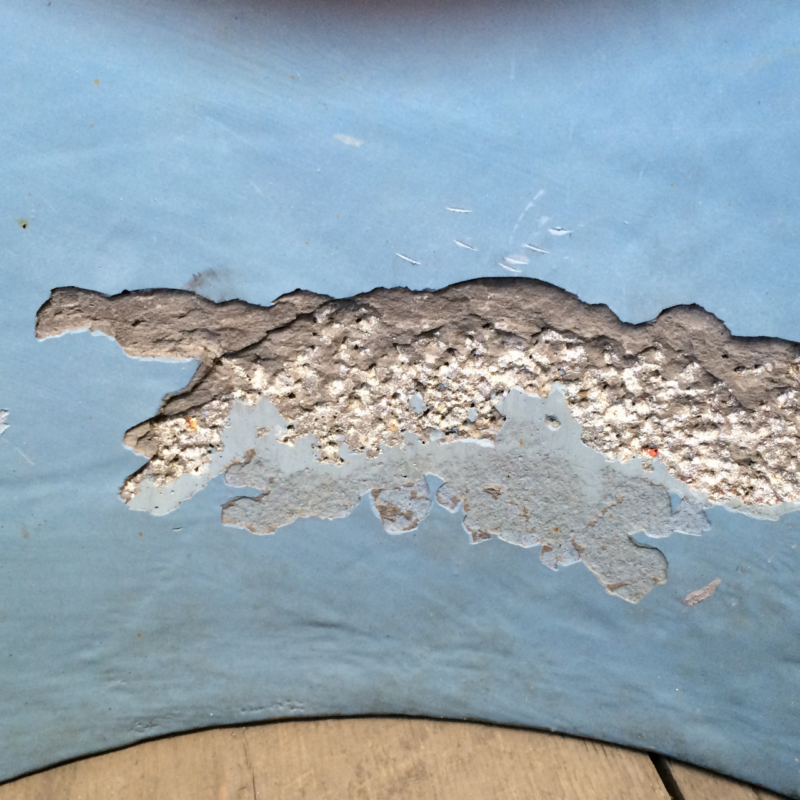

A Kamewa propeller cone at a marine facility in Italy required urgent repair following the discovery of extensive erosion and corrosion damage. Prolonged exposure to high velocity seawater and turbulent flow conditions led to severe metal loss and pitting. The surface degradation compromised the hydrodynamic efficiency of the propeller cone, directly impacting the vessel’s fuel consumption and overall operational reliability. Localised pitting posed a high risk of through wall failure, which would necessitate a costly and time consuming full component replacement. The client needed a repair solution that could be completed during a standard dry dock window to avoid extended operational downtime.

The Solution

Results & Benefits

- Successfully restored to its original structural integrity and performance specifications

- Established a durable 1000 micron barrier engineered to withstand harsh marine environments

- Significantly prolonged the lifespan of the propeller cone, reducing costs by avoiding of a full replacement

- Improved vessel reliability and minimised the risk of unplanned downtime

- Reduced long term maintenance costs by providing a high performance, wear resistant surface

- Verified the repair through rigorous ISO 8501/4 surface preparation standards for guaranteed coating longevity

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.