Wastewater Pump Repair: A Case Study

Discover More

14th January 2026

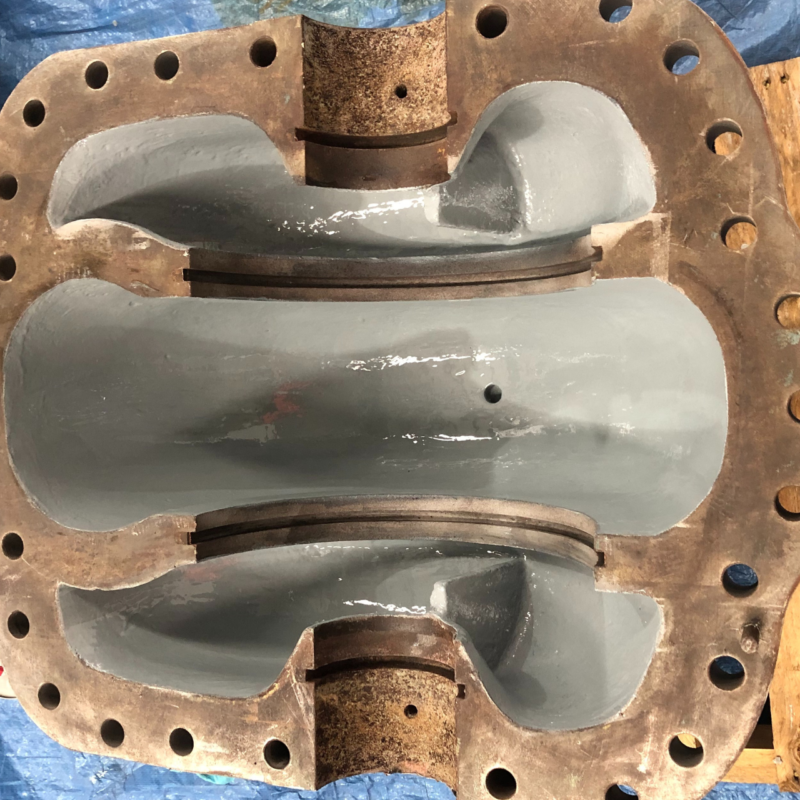

A split horizontal cast iron wastewater pump at a chemical plant suffered extensive pitting and wear from prolonged exposure to harsh process fluids. The damage significantly reduced performance and increased the risk of costly downtime. An urgent wastewater pump repair was needed to restore functionality, prevent further degradation, and ensure reliable operation in demanding conditions.

Resimac’s Wastewater Pump Repair Solution

- Pump surfaces were thoroughly cleaned and prepared to ensure optimal adhesion of repair materials.

- Damaged areas resurfaced using 101 Metal Repair Paste.

- Coated with two layers of 203 Super Flow for abrasion and corrosion resistance.

Application Details

The wastewater pump underwent an extensive cleaning process to remove contaminants and prepare the surface for repairs. This step was crucial to achieving a strong bond between the substrate and the repair materials. Pitted and damaged areas were meticulously restored using Resimac 101 Metal Repair Paste, which filled cavities and returned the pump to its original profile.

To ensure long term protection, the repaired pump was coated with two layers of Resimac 203 Super Flow. The first coat, applied in grey, formed a durable base layer to enhance the system’s resistance to harsh process fluids. The second coat, in blue, added an extra level of defence, particularly against abrasion and chemical attack. The dual layer system ensured comprehensive protection for the pump’s interior surfaces, reducing the risk of recurring damage and premature failure.

Products Used

Results and Benefits

The repair not only restored the pump’s performance but also introduced a protective barrier tailored to withstand the plant’s demanding chemical environment. This solution reduced the risk of unforeseen failures, offering the facility greater confidence in its wastewater management system. With enhanced durability and fewer maintenance requirements, the repair contributed to smoother operations, allowing resources to be redirected to other critical areas of plant activity.

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.