Worn Shaft Repair: Power Generation, UK

Discover More

28th November 2024

Industry: Power

Location: UK

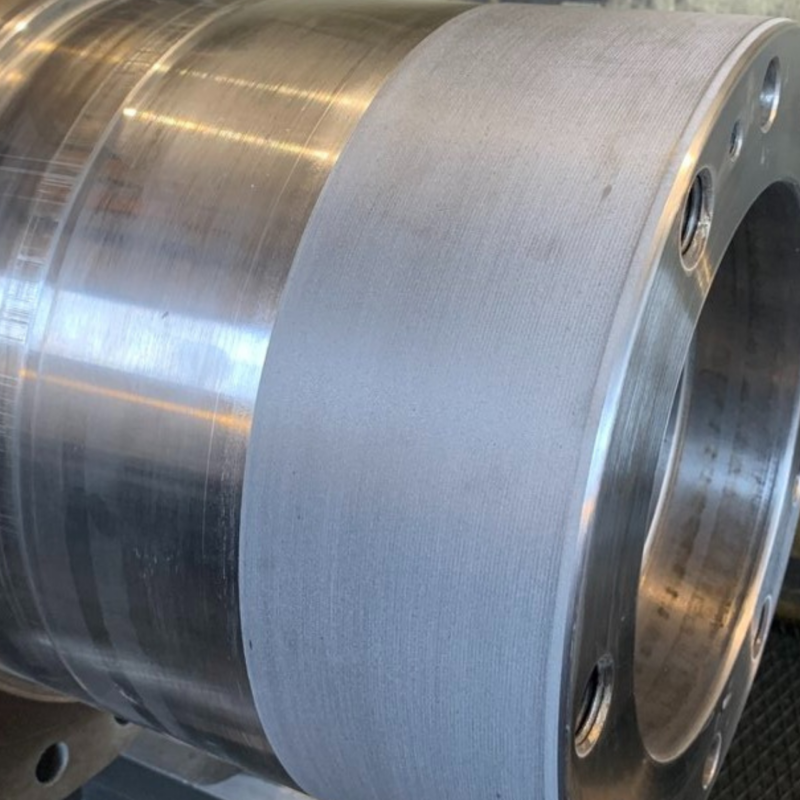

Application: Worn Shaft Repair

Products: 101 Metal Repair Paste

The Challenge

A power generation facility identified significant mechanical wear on the end of a critical drive shaft. The degradation compromised the component’s original dimensions, threatening equipment performance and operational reliability. Left unaddressed, the wear posed a high risk of failure and prolonged service disruptions. Given the lead times and capital expenditure required for a full replacement, the facility required an immediate, high precision resurfacing solution to restore the asset’s structural integrity. This specific worn shaft repair needed to be durable and reliable.

The Solution

Results & Benefits

- Returned the critical shaft to its exact original dimensions and structural integrity

- Ensured continued reliable operations using a worn shaft repair system trusted across global power generation facilities

- Significantly reduced cost by avoiding full replacement and installing a replacement shaft

- Rapid repair and curing times ensured a swift return to service

- Increased the component’s lifespan while reducing the frequency of future maintenance

Gallery

Categorised in: News, Project Profiles

Get in Touch

If you need help with a similar issue please contact Resimac and our team of experts will be happy to help.